SO YOU WANNA BE A WELDER?

SO YOU WANNA BE A WELDER? DRUG TESTS IN THE WELDING INDUSTSRY For a long time, secondary educators have pushed college as the only avenue to success. In recent years […]

WELDER CERTIFICATION VS QUALIFICATION

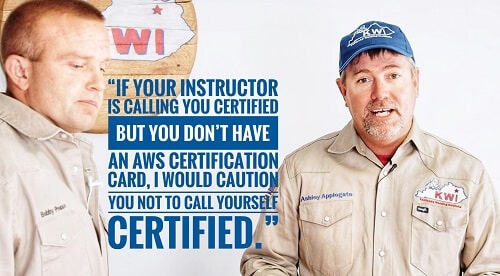

WELDER CERTIFICATION VS QUALIFICATION WELDER CERTIFICATION VS QUALIFICATION There is a lot of confusion on the difference between certification and qualification. According to the American Welding Society certification is only […]

MORE THAN JUST A WELD SCHOOL

MORE THAN JUST A WELD SCHOOL MORE THAN JUST A WELD SCHOOL When planning your future, it is important to consider the changes that lie ahead. In 2018, OSHA mandated […]

WHY NCCER IS WHERE ITS AT

WHY NCCER IS WHERE ITS AT If you know about NCCER then you understand why KWI was eager to adopt their curriculum and join their membership as an Accredited Training […]

SAFETY FIRES UP YOUR RESUME

SAFETY FIRES UP YOUR RESUME In the trades companies are continually fighting to keep accidents and injuries from happening. In fact, companies are scored with an EMR (experience modifier […]

WHO SAYS YOU DON’T NEED WELD CERTS?

WHO SAYS YOU DON’T NEED WELD CERTS? 2. Hold Your Hands High, Elbows Low & Move Your Head Bobby Pease: Alright, let’s talk Accredited Testing Facility. So, the Kentucky Welding Institute […]

3 SECRETS TO SUCCESS IN THE WELDING INDUSTRY

3 SECRETS TO SUCCESS IN THE WELDING INDUSTRY 2. Hold Your Hands High, Elbows Low & Move Your Head Bobby Pease: Hey, so there’s three quick things that companies and […]

DRUG TESTS IN THE WELDING INDUSTSRY

DRUG TESTS IN THE WELDING INDUSTSRY Bobby: Alright, so some guys are asking how do you get that first job? I think that the easy answer to that is there’s […]

A TIP ABOUT BEING ON TIME

A TIP ABOUT BEING ON TIME The old adage “Time is money” has some truth behind it. Your biggest investment is your minutes & hours each day! Stewarding it well […]

DO A LITTLE EXTRA

DO A LITTLE EXTRA Welding is hard work and it pays off when you do the right thing. One of the “right things” to do is to bring a little […]